|

|

Solvent Recyclers, Distillation and Reclaim

Systems

Reduce Solvent

Cost with In-House Recycling and Recovery

•

Phone: 262 695-7536

|

.png)

.png) |

|

|

|

|

|

|

|

|

.png)

.png)

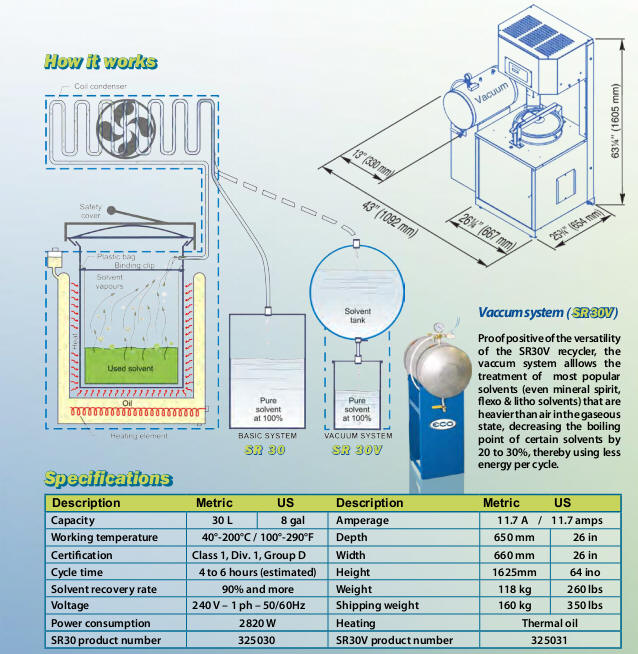

ISTpure SR 30 & 30V (8 gallons)

Options include:

Vacuum System

Dirty Solvent Loading Pump

Nitrocellulose Protection

Stainless Steel Condenser |

|

|

|

|

|

.png)

.png)

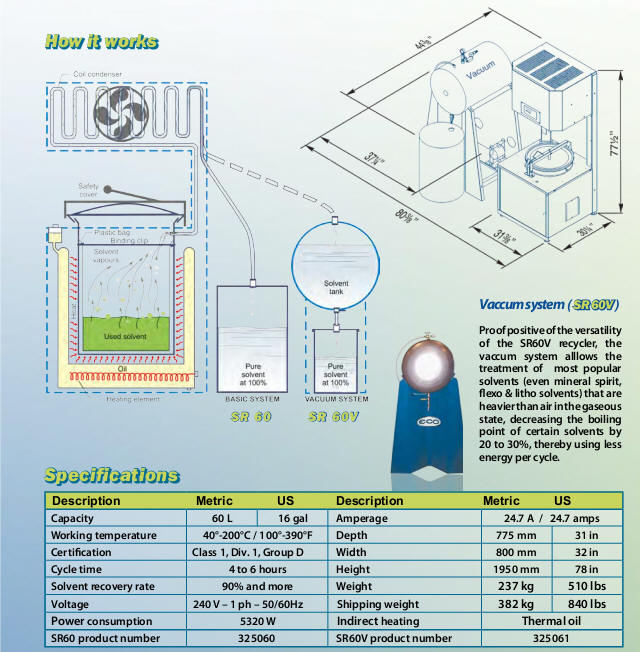

ISTpure SR 60 & 60V (16 gallons)

Options include:

Vacuum System

Dirty Solvent Loading Pump

Nitrocellulose Protection

Stainless Steel Condenser |

|

|

|

|

|

.png)

.png)

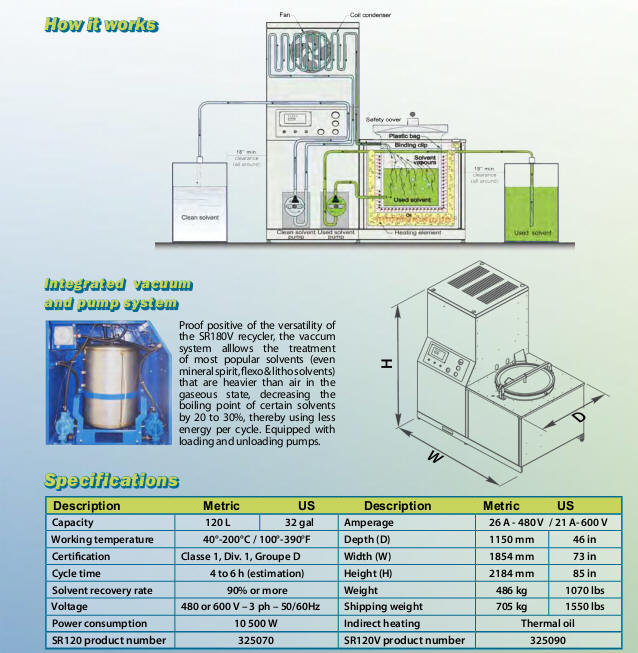

ISTpure SR 120 & 120V (32 gallons)

Options include:

Vacuum System

Nitrocellulose Protection

Auto-fill System

Stainless Steel Condenser

Remote Status Light Column

Still Bottom Basket

Crane for removal of Basket

|

|

|

|

|

|

.png)

.png)

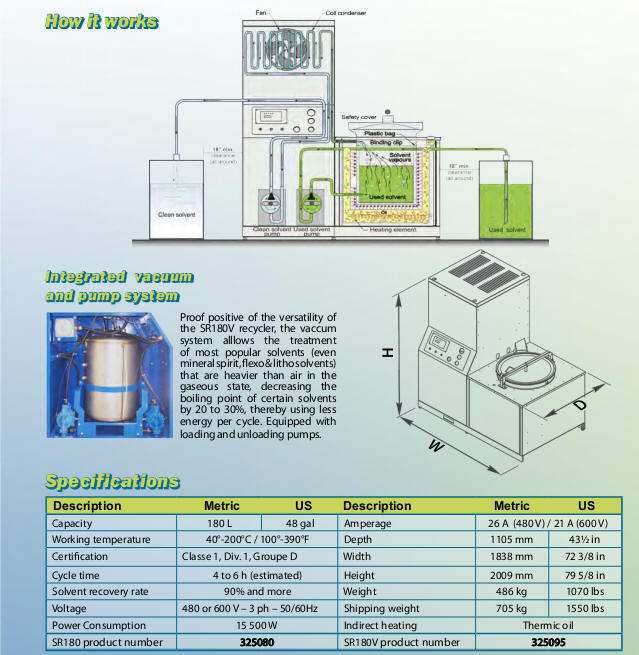

ISTpure SR 180 & 180V (48 gallons)

Options include:

Vacuum System

Nitrocellulose Protection

Auto-fill System

Stainless Steel Condenser

Remote Status Light Column

Still Bottom Basket

Crane for removal of Basket

|

|

|

|

|

.png)

.png)

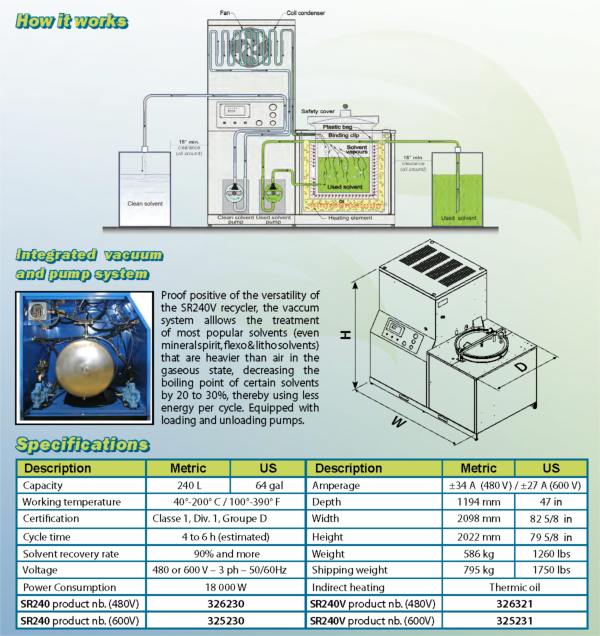

ISTpure SR 240 & 240V (64 gallons)

Options include:

Vacuum System

Nitrocellulose Protection

Auto-fill System

Stainless Steel Condenser

Remote Status Light Column

Still Bottom Basket

Crane for removal of Basket

|

|

|

|

|

|

.png)

.png)

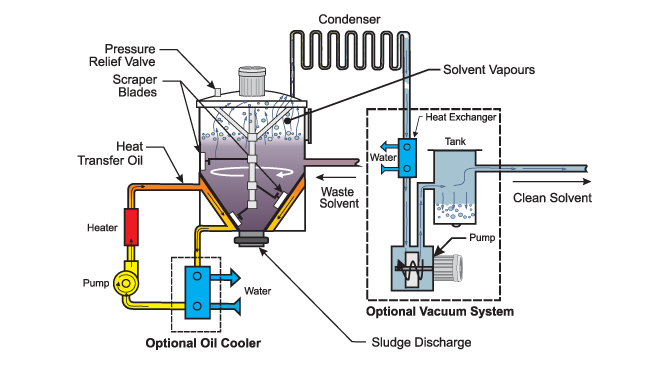

ISTpure SRC Series

This ISTpure SCR

Solvent Recyclers allow used solvent recycling in

continuous-flow or batch evaporative distillation processes.

Units available in tank capacities of 30, 60, 120, 180 and

240 liters and deliver production yield of up to 375 liters

per hour.

Waste solvent automatically enters the distillation vessel

using standard vacuum pump provided with solvent recovery

still. Heated thermal oil re-circulates in distillation

vessel jacket. Solvent sludge is heated to programmed

temperature to create vapor which exits boiler and travels

through condenser. Scrapper rotates at bottom of

distillation vessel to keep it clean and avoid calcination

of chemicals. Entire process is controlled by PLC.

Clean condensed solvent

exits to storage vessel ready for reuse.

Available with Nitrocellulose protection options for

applications in the flexographic press wash-up, wood cabinet

coatings and similar applications. |

|

|

|

|

|

.png)

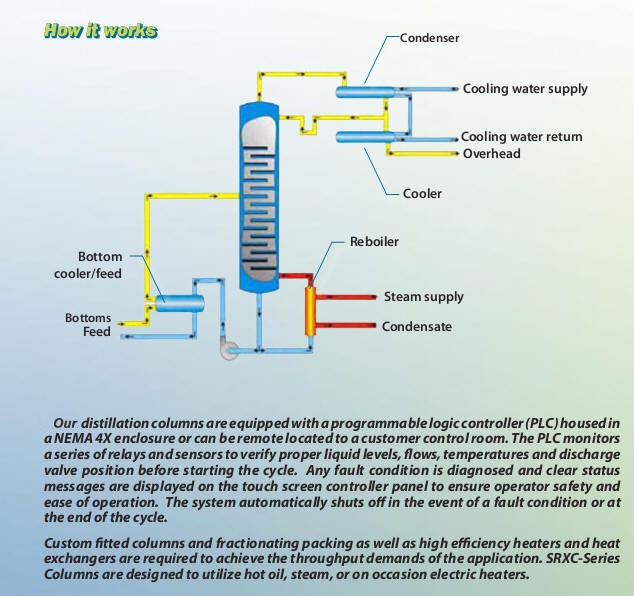

.png) Custom Distillation Columns

The ISTpure SRXC-Series is a completely

automated chemical distillation column designed to address a high

purity chemical purification application in multiple industries. The

system is designed to remove water, other chemicals, and or

contaminants from the chemical being purified.

A specially designed fractionating column with a

reflux stream is used to separate the materials in a continuous mode

while keeping a flow rate of up to 25 – 5,000 gph on a 24 hour per

day basis. |

Contact Information

For information and/or to

discuss your specific needs and application, please contact us at:

- Telephones:

-

Main office: 262-695-7536

-

Tim A Koenings, Sales & Product

Manager, ext:102, Cel: 262 527-1946

- Richard I McDonald, President,

ext:103

-

- Fax:

- 262-695-7536

Addresses:

-

Corporate Offices: (Invoicing and bill payments)

-

1092 Riverway Court, Pewaukee WI 53072

-

Sales

& Service Offices, Test & Demo Facility, Warehouse:

- N15 W22120

Jericho Drive, Unit #6, Waukesha WI 53186

|

|

|